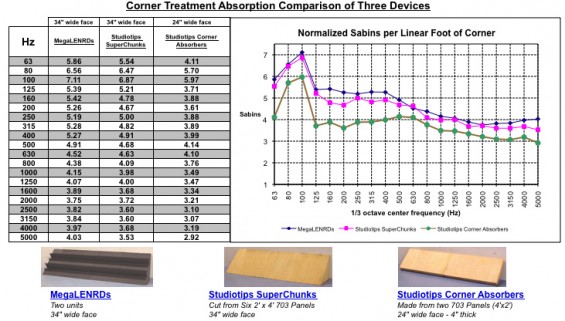

Acoustic foam has been used by manufacturers such as Auralex and Sonex for decades. The benefits over other materials is that it can be easily manufactured into various designs and contours that enhance the absorption characteristics of the foam. There are many discussions on the web about the effectiveness of acoustic foam vs fibreglass. An interesting laboratory analysis was performed at Riverbank acoustic laboratory some years back comparing the Auralex MegaLENRD product vs a similar volume fibreglass “SuperChunk” corner trap design. The laboratory results shows the Auralex acoustic foam product slightly outperforming the “SuperChunk”. Both acoustic foam and fibreglass are effective acoustic absorbers, there is very little between them. What is important is that a corner bass trap has sufficient volume to be effective in absorbing high energy low frequencies. One practical issue with fibreglass is that when impacted or disturbed is produces a fine dust that floats in the air. This dust is very irritating to the throat and lungs. In SoundAcoustics modular slot panels we use polyester in preference to fibreglass as it can be handled without the need for protective equipment .

The Auralex MegaLERND has the same front face dimensions as the SoundAcoustics LF60 bass trap. The LF60 gains additional low frequency absorption with the addition of the unique reflective insert.